The World's First High-Performance Cellulose Lithium-Ion Battery Separator

Creating Novel Products That Satisfy the Requirements of the Modern World

NIPPON KODOSHI CORPORATION's LIB separators are used in a variety of automotive and industrial battery applications around the world.

Overview

Lithium-ion batteries are a type of secondary batteries that can be repeatedly charged and discharged. Compared to other secondary batteries, they have the benefit of a high energy density.

Although their main application was mobile phones and laptops, in recent years, demand has been growing for their use in a variety of small to large devices such as EVs, drones, and stationary cell systems.

Our Cellulion® lithium-ion battery (LIB) separator is the world's first high-performance LIB separator made of 100% cellulose.

Comparison of Cellulion® with Porous Film and Inorganic Coating Film Separators

| Cellulion® | Porous film | Inorganic coating film | |

|---|---|---|---|

| Electrolyte wettability | ✓ | ||

| Low resistance | ✓ | ||

| Heat resistant | ✓ | ||

| High strength | ✓ | ✓ | |

| Shielding properties | ✓ |

Cellulion® is made from 100% plant-based LENZING™ regenerated cellulose fibers developed by Lenzing AG. Compared to conventional porous and inorganic coating films, it has slightly lower strength and shielding performance but has superior electrolyte wettability, low electrical resistance, and high heat resistance. This is expected to improve overall battery performance.

Note: LENZING™ is a registered trademark of Lenzing AG.

Over our ten years of experience in the mass production of LIB separators, our products have been used automotive and industrial battery applications around the world.

Cellulion®

Advantages of Cellulion® ① (Electrolyte Wettability)

Excellent Electrolyte Wettability with High Liquid Retention

Cellulion® has excellent affinity for various electrolytes and has superior liquid retention performance. This improves the battery cycle life and low-temperature performance. It also has a significantly shorter electrolyte impregnation time and leads to lower production costs.

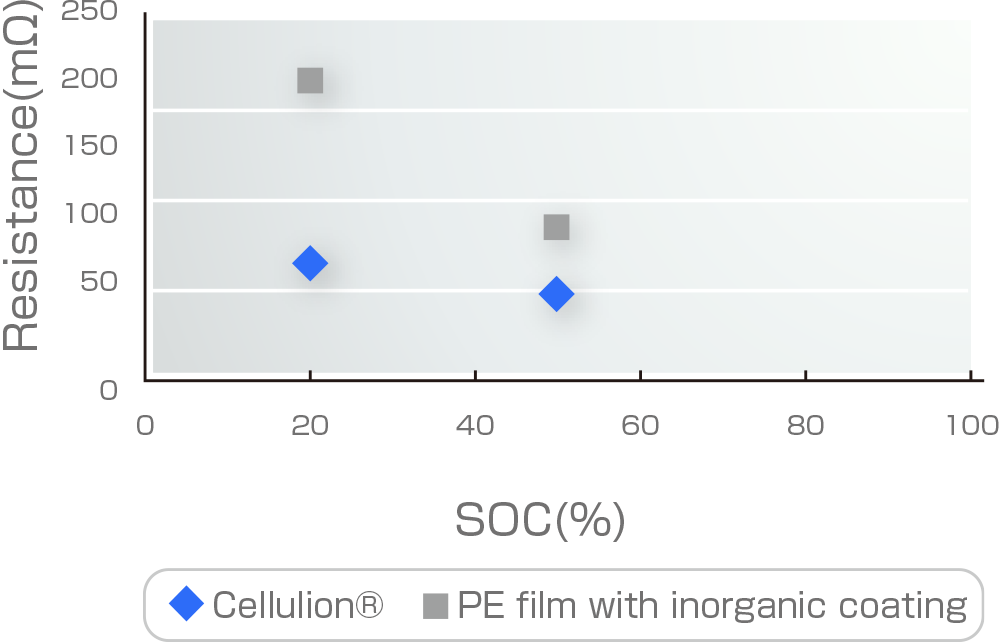

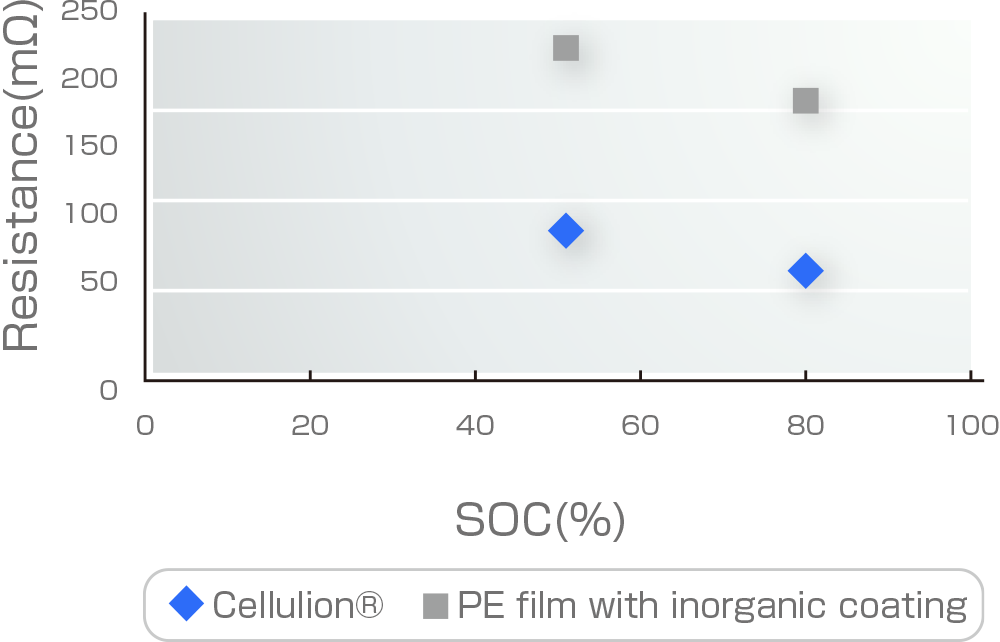

Advantages of Cellulion® ② (Low Resistance)

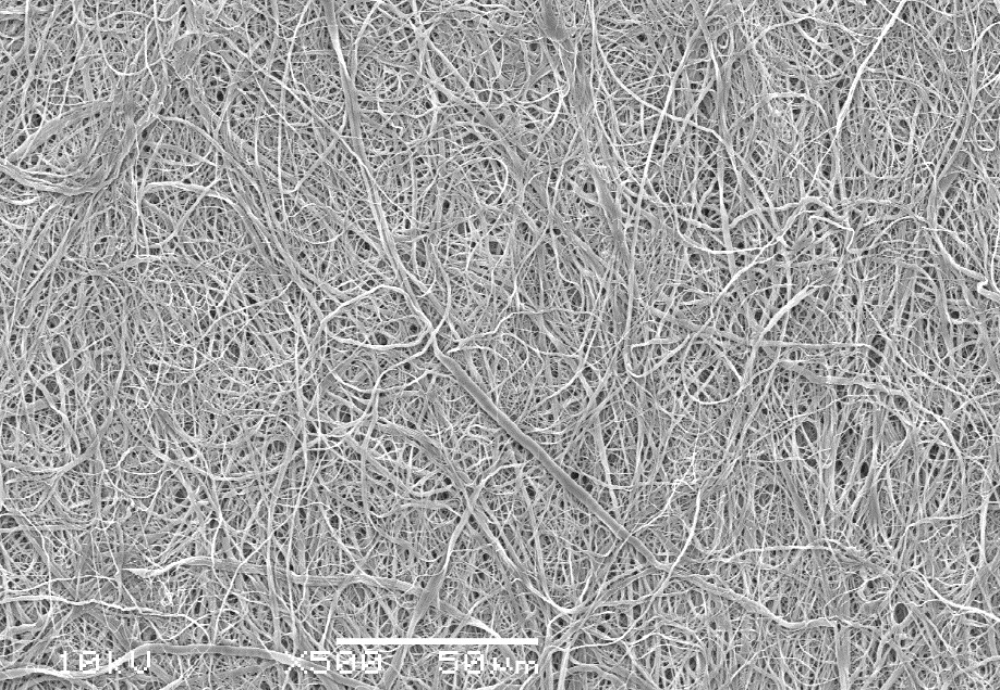

Achieves good lithium-ion conductivity due to high porosity and highly dense structure.

The highly dense yet porous structure enables fast movement of lithium ions between the cathode and anode and reduces internal resistance during charging and discharging.

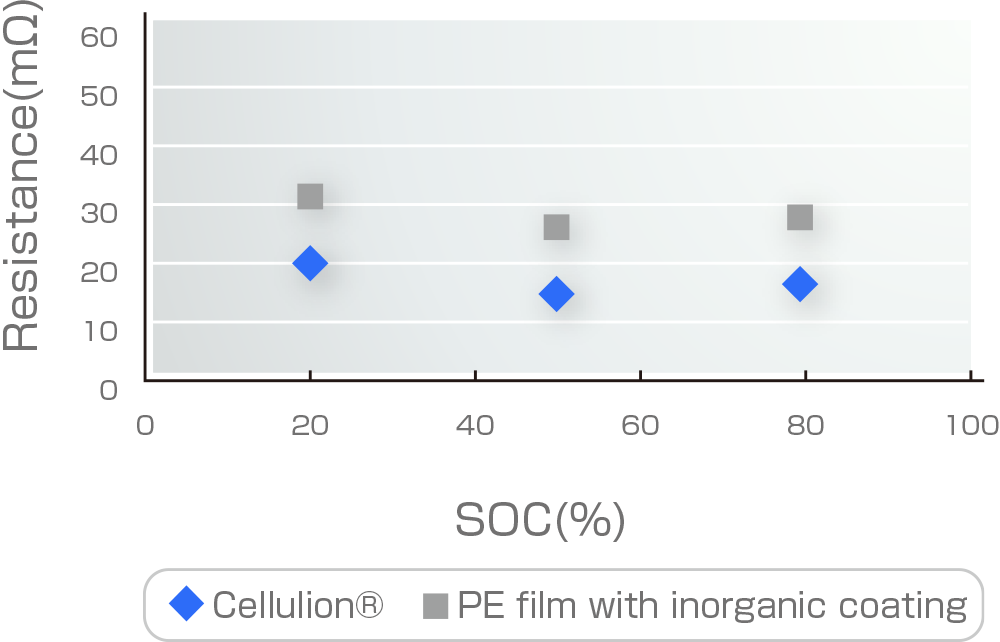

Note: The figure below compares the resistance during charging and discharging under various conditions.

Input/Output Test (30°C)

Resistance Comparison (Input)

Input/Output Test (30°C)

Resistance Comparison (Output)

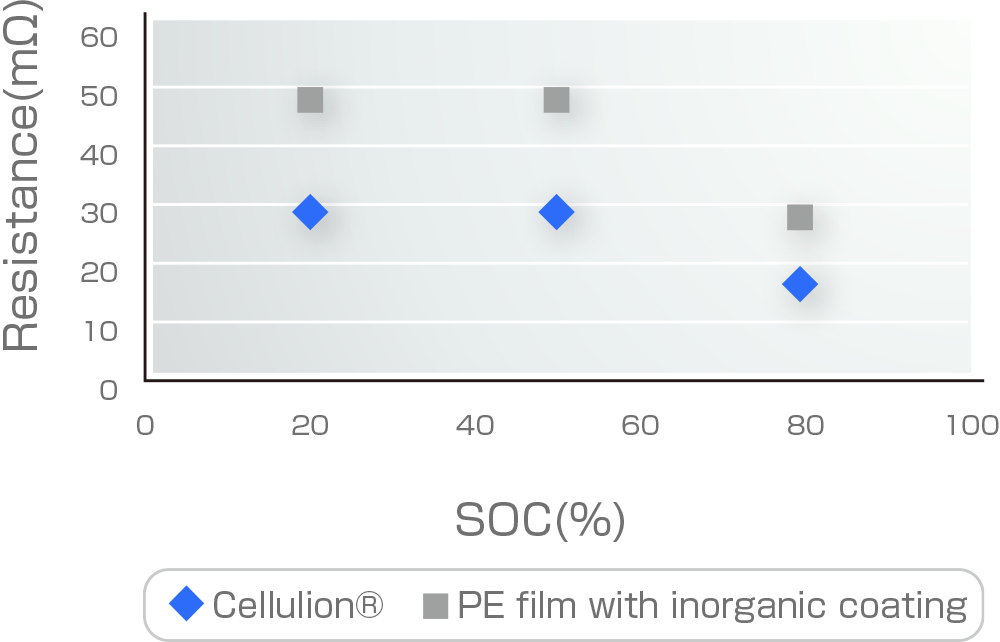

Input/Output Test (-20°C)

Resistance Comparison (Input)

Input/Output Test (-20°C)

Resistance Comparison (Output)

Cell Configuration

Capacity: 1,000 mAh

Cathode: NCM (523), Anode: Hard carbon, Electrolyte: 1MLiPF6 EC/DMC/EMC

Each SOC was charged for 12 seconds (input) and then discharged for 12 seconds (output). The resistance was then calculated from the current and voltage at the 12th second.

Advantages of Cellulion® ③ (Heat Resistance)

High Heat Resistance Due to Being Made of 100% Cellulose

-

Cellulose has significantly superior heat resistance compared to polyolefin-based porous films. The greater dimensional stability at high temperatures allows for improved productivity through high-temperature drying.

It also improves battery safety.

Advantages of Cellulion® ④ (Low Environmental Impact)

A Unique 100% Plant-Based Separator for a Sustainable Future

-

It contains no petroleum-based materials.

As it is extremely environmentally friendly and contributes to the goal of a decarbonized society, it is the perfect choice for future applications.

Note: NIPPON KODOSHI CORPORATION is committed to protecting the global environment, and conducts corporate activities that have minimal impact on people and the environment. -

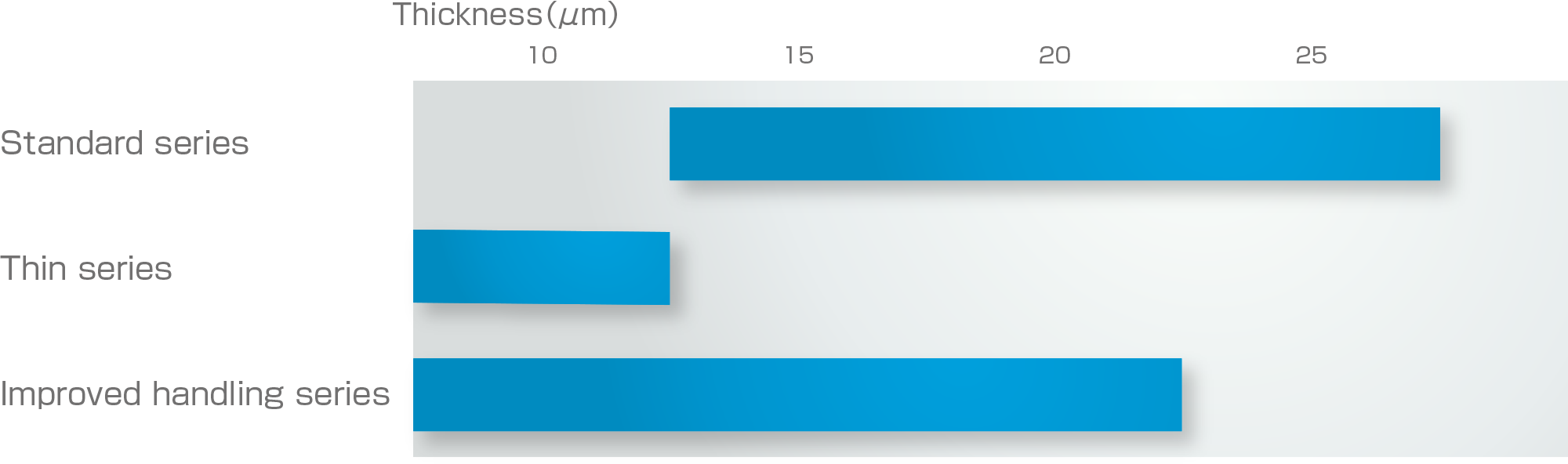

Product Lineup

The stacked structure of fibrillated fibers forms a highly dense yet porous paper layer. It enables fast movement of lithium ions between the cathode and anode and reduces internal resistance during charging and discharging.

Lithium-Ion Battery Separator Lineup

Feel free to contact us regarding any other specifications you may require.