Supports a Wide Range of Applications from Home Appliances to Automobiles

NIPPON KODOSHI CORPORATION's separators for aluminum electrolytic capacitors are highly regarded as the global industry standard.

Overview

Aluminum electrolytic capacitors are one of the most critical components used in the electronics products and are used in all devices that are powered by electricity.

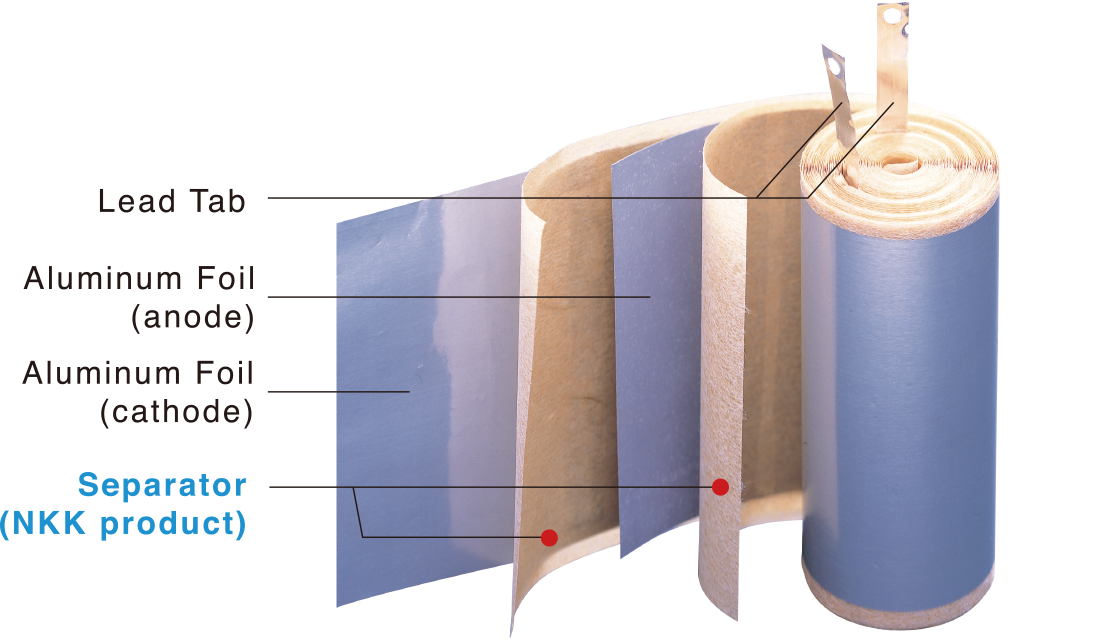

A separator is the paper placed inside aluminum electrolytic capacitors to retain the electrolyte and prevent short circuits.

In order to retain a sufficient amount of electrolyte, the separator must have enough porosity for electrolyte retention. However, the separator must also have high denseness to prevent a short circuit between the anode and cathode.

As part of our goal to satisfy these seemingly conflicting requirements, we have overcome a variety of obstacles by utilizing our novel technology that was cultivated over several years through close relationships with our customers.

Quality is Built into Our Processes

Our philosophy regarding manufacturing is based on the concept that instead of eliminating defects through inspections, individuals in the team involved in each product process should be responsible for maintaining quality. This also facilitates the thorough removal of impurities and foreign substances during the processes, resulting in our proven track record in high-reliability applications such as automotive.

We have introduced a traceability system, that allows us to trace the level of quality all the way back to the raw materials.

Creating Advanced Products

We continue to actively develop and improve products to satisfy our customers' requirements.

This has resulted in a comprehensive lineup of more than 200 products.

Separators for Medium- and High-Voltage Aluminum Electrolytic Capacitors

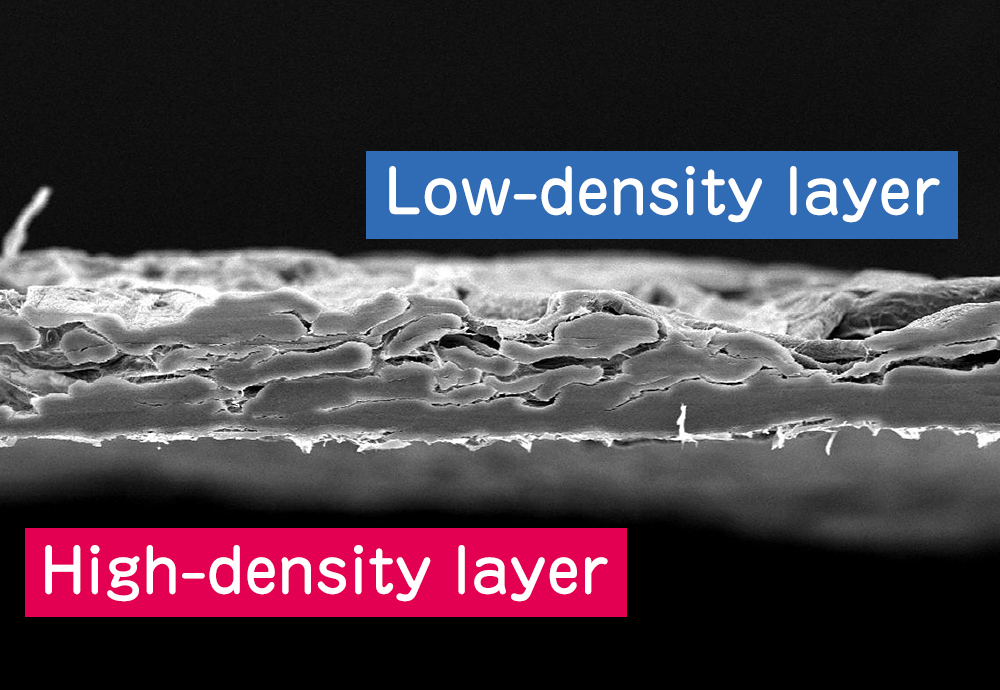

For intermediate- and high-voltage applications, the main configuration is to use double-layer (duplex) separators that are made by layering both high-density and low-density separators. The high-density side of this double-layer separator secures the high voltage resistance, while the low-density side retains the electrolyte.

High-density layer

Low-density layer

Separators for Low-Voltage Aluminum Electrolytic Capacitors

-

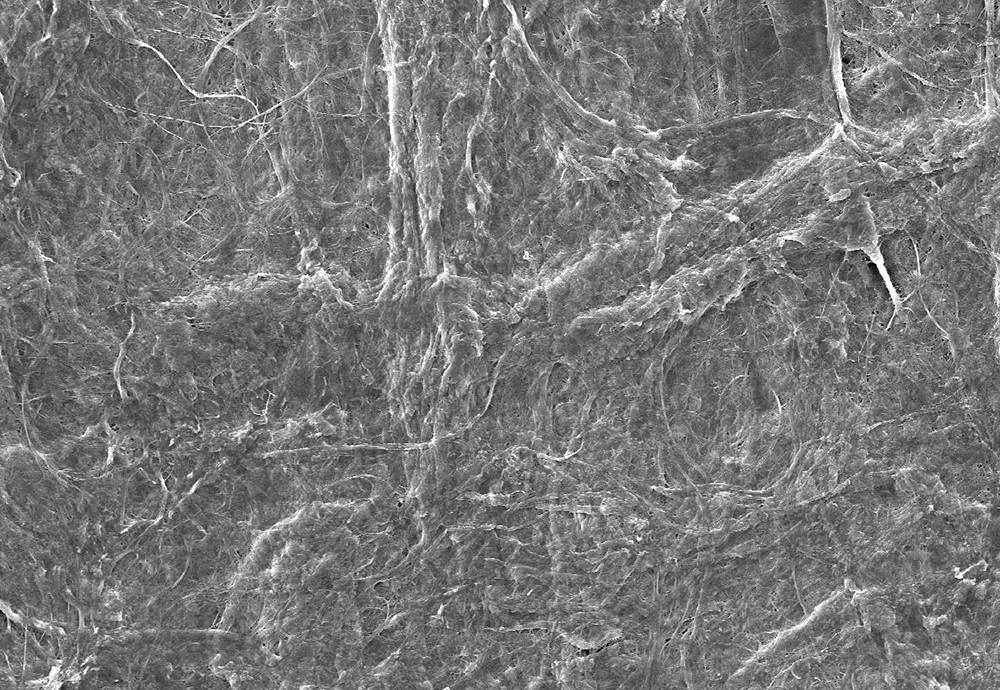

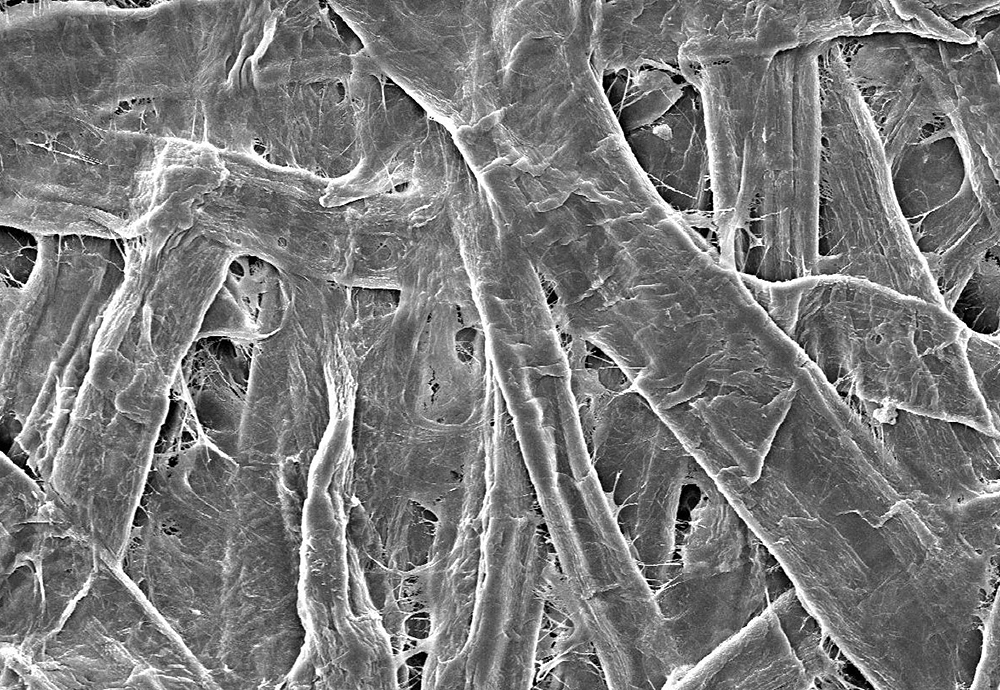

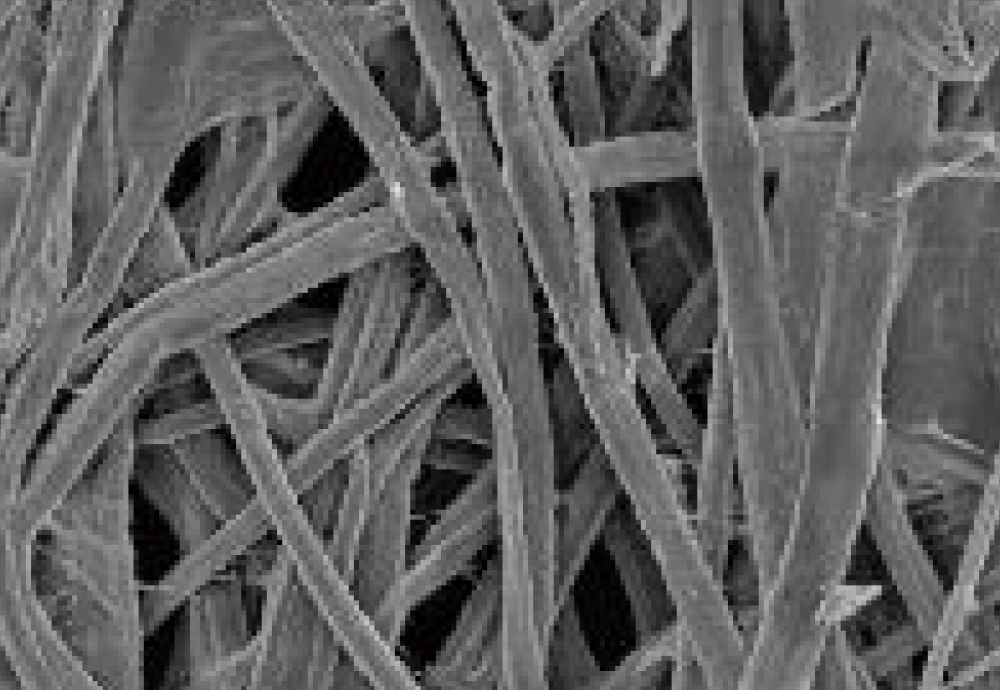

For low-voltage applications, separators made of natural cellulose fibers as well as special rayon fibers are used to further improve reliability. The special rayon fibers are beaten to produce fine fibrils, resulting in a dense separator.

For intermediate to high-voltage as well as low-voltage applications, we have a comprehensive lineup of products to suit various capacitor voltages, sizes, and applications. -

Special rayon fibers

Natural cellulose fibers

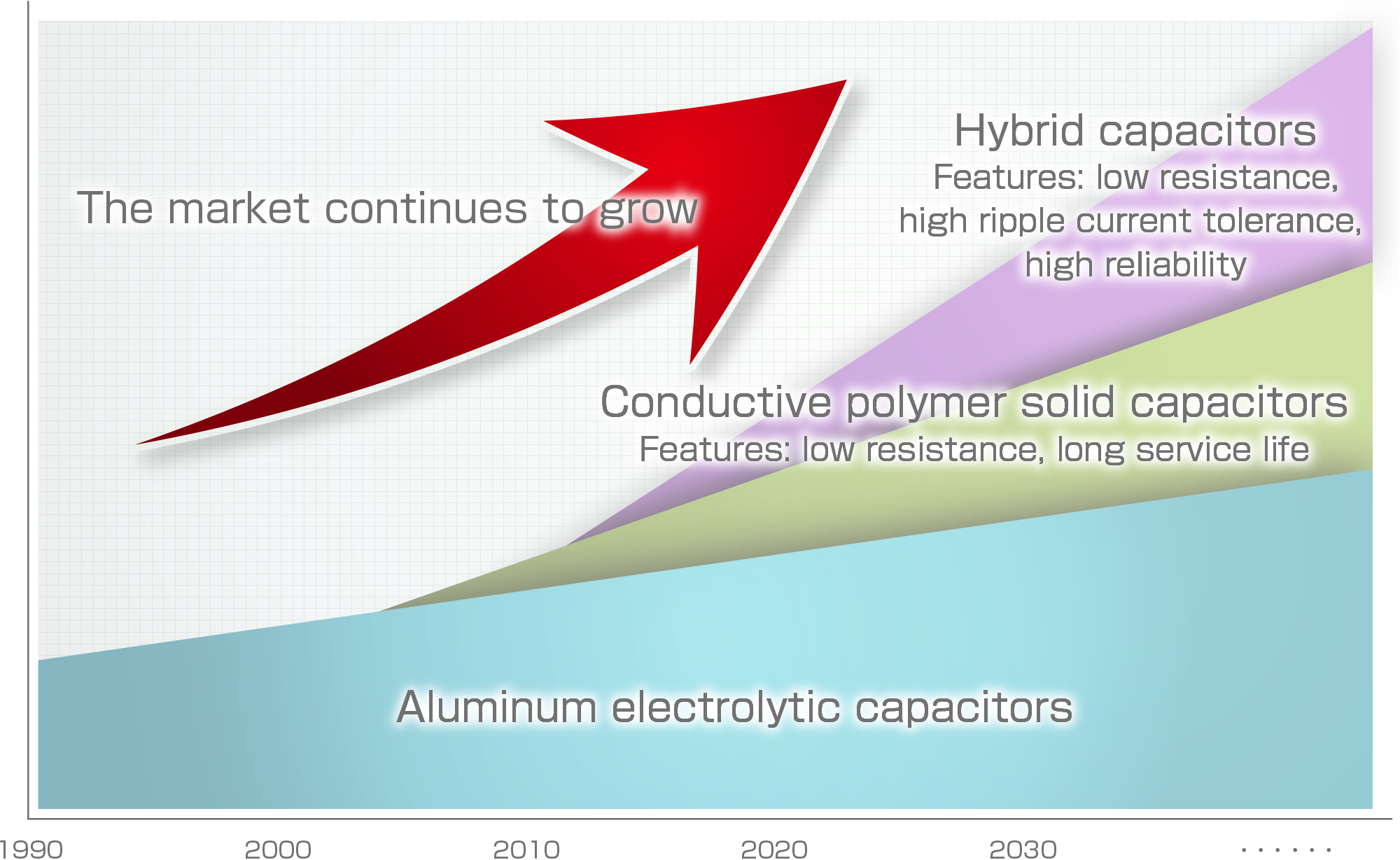

Challenges Faced by the Continually Evolving Capacitor Industry

Building upon the range of technology and expertise we have cultivated for conventional separators used in aluminum electrolytic capacitors, we are actively developing new separators for conductive polymer solid capacitors and hybrid capacitors, which have been gaining a lot of attention in recent years.

Anticipating the needs of this growing market, we offer products that use not only cellulose fibers but also chemical fibers.

Trends in the Market

Separators for Conductive Polymer Solid Capacitors

Conductive polymer solid capacitors employ a conductive polymer instead of an electrolyte. Compared to conventional aluminum electrolytic capacitors, they have lower ESR, better frequency characteristics, and less characteristics fluctuation due to temperature and voltage.

Due to differences in the electrolyte and usage environment, we are developing separators that have better impregnation, chemical resistance, and heat resistance compared with conventional separators used in aluminum electrolytic capacitors.

Separators for Hybrid Capacitors

Hybrid capacitors use both a conductive polymer and an electrolyte, which allows them to utilize the advantages of both types of capacitors. They utilize the low ESR performance and high ripple current tolerance of conductive polymers as well as the healing function of electrolytes. They are becoming more common in applications that require high safety and performance standards such as automobiles.

We are currently developing separators for hybrid capacitors that have the characteristics required of both conductive polymer solid capacitors and conventional aluminum electrolytic capacitors.

Examples of Applications

Solar power

Air-conditioners

PCs

TVs

Battery chargers

Vacuum cleaners

Washing machines

Refrigerators

Quick chargers for EVs

5G base stations